February’s Group meeting was held at WETRC in Auburn. Thank you Scott Hemingway for hosting this month. The meeting was called to order at 10:05am by Past Chair Mick Holte, introductions were made and those in attendance were: Robert Main On-Site Testing, Jason Burnett Archer Construction Inc., Tim Cantwell Woodinville Water District, Dominic McLaughlin McLaughlin’s eninsula Backflow Service, Jason Moe Batman Testing, Branden Clark City of Dupont Public Works, Debbie Crooks City of Kent, Julie Davis City of Marysville, Richard Dochnahl Mt. Si Plumbing, Andrew Piekarski Silver Lake Water & Sewer District, Robert Eastwood Retired, Fred Foreman City of Dupont, Chris Sutton Backflows Northwest, Scott Hemingway WETRC, Heidi Hiatt City of Kirkland, Scott Hallenberg City of Tacoma, Cynthia Snyder Backflows Northwest, Past Chair Mick Holte City of Renton, Treasurer Dennis McLaughlin Retired BAT and Secretary Katarina Hirai Silver Lake Water & Sewer District.

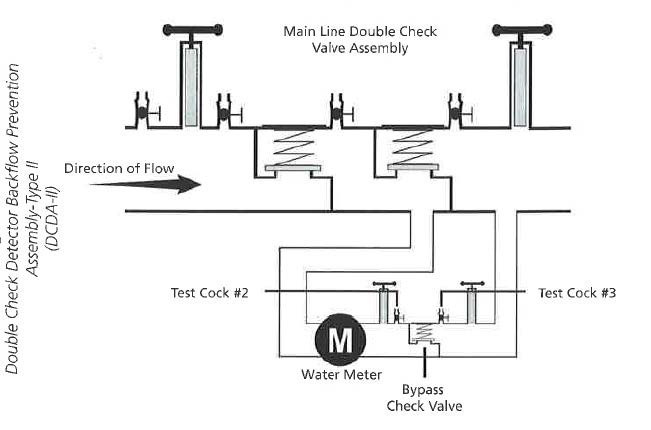

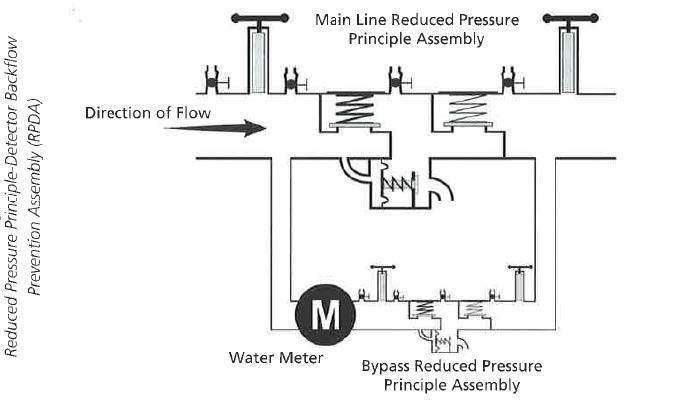

The Group Treasurer Dennis reported The Group’s account balance as of February 20, 2019 was $31,098.84 with earnings of $354.36 and payments of $50.29 since January 1, 2019. The floor was then open to old business. Mick was asked for an update on his communications with Brightwater in regards to moving this year’s Group Seminar to their facility. Mick reported he was trying to contact the venue, but had not received communication back. He will follow up with them. The Insurance Committee was then asked about their progress in finding a legal expert in Liability Insurance needs for nonprofit organizations. The Committee reported they had not started the process yet, but Scott Hemingway committed to sending out an email to the rest of the Insurance Committee members to begin their search. This closed old business. Jason Moe then requested that The Group look into allowing for online payments of Group dues. Jason suggested this may increase membership as it would be more convenient for individuals to make the $10.00 payment. Katarina Hirai volunteered to look into potential options for The Group. The floor was then given over to Scott Hemingway for his presentation on Type II Detector Assemblies. Though these assemblies have been approved since 2015, many BATs and CCSs have not seen them in the field. Similar to Type I Assemblies, Type II Assemblies detect unauthorized water use through the use of a meter and the head loss across the main line must be greater than the head loss across the bypass so that at low flows water is forced through the meter and the bypass. The difference between Type I and Type II Assemblies is that instead of having two bypass check valves plumbed before the first mainline check valve, Type II Assemblies have only one bypass check valve plumbed after the first main line check valve. Similar to Type I Assemblies, the bypass check valve will have a separate make, model, and serial number on the bypass check valve and the bypass check valve must be installed by the factory. Advantages of the Type II Assemblies include lower head loss across the entire assembly, which is important in fire system design, and the cost to design and manufacture them is lower than Type I Assemblies.

Scott then passed out WETRC’s cliff notes of the USC Manual testing procedures for both Type II and Type I Detector Assemblies (included at the end of this newsletter). It was noted that the biggest difference in testing Type II assemblies was that a value (greater than 1.0 psid) must be reported for the single bypass check on both DCDAs and RPDAs. This is not intuitive for Type II RPDAs as for Type I RPDAs no value is recorded, only that it closed tight. For Type II RPDAs, a value must be recorded for the bypass check valve. It was also noted that per the 10th Edition of the USC Manual of Cross-Connection Control, water meter readings should be recorded at the beginning and end of testing during the testing of any Detector Assembly (both Type I and Type II) to notify the water purveyor that the water usage detected by the meter was not unauthorized use. A discussion then ensued on whether these recordings should be included on the test report. Chris Sutton expressed concern that current backflow software for both purveyors and BATs don’t have a field to enter in these meter readings. Dennis McLaughlin also expressed concern that electronic form submission does not allow for this information and that the purveyor would need to be looking at the form in order to receive this information. Scott also noted in his presentation that when testing any type of Detector Assembly, the tester must verify flow through the bypass by verifying the water meter indicates flow. Sample test forms for Type II Assemblies were passed out (included at end of newsletter). These forms include all State required information, some suggested information, and are organized in the order of the testing procedure. Concerns were voiced over the sample test report from BATs as they would prefer to complete two test reports for both Type I and Type II Detector Assemblies. At this time, some purveyors accept one test report for Type II Detector Assemblies, while others accept two. Scott wanted to remind everyone that whether it is two report forms or one, it is still only one assembly, whether it be Type I or Type II. Thus, if a repair is required on the bypass or mainline assembly, both the bypass and mainline assembly must be retested after the repair per USC testing procedures.

The Group then moved to the WETRC’s Wet Lab to see examples of Type I and Type II Detector Assemblies. The difference in size of a Type I versus a Type II assembly was remarkable, with the Type II being more compact and thus a good option for retrofits or smaller mechanical rooms.

Finally, a drawing was held for three portable cell phone charges. Congratulations to Cynthia Snyder, Chris Sutton, and Jason Burnett!

The meeting adjourned at 12:10pm.

The next meeting will be the BAT Forum at the La Quinta in Tacoma at 9am. Remember to renew your membership dues for 2019 if you haven’t already done so.